Cheap green hydrogen is not a dream: group from National Cheng-Kung University develops groundbreaking high-entropy thin-film catalyst

Edited by and images credit to News Center.

Sustainable green energy is essential for human development. Recently, researchers have focused on producing hydrogen and oxygen through water-splitting reactions. Since catalysts are required for both hydrogen and oxygen production, preparing high-efficiency catalysts has become the primary goal of this research.

With the support of National Cheng Kung University, Professor Jyh-Ming Ting and his Ph.D. student Siang-Yun Li have successfully developed a high-entropy-alloy thin-film catalyst by combining vacuum processes with high-entropy alloys. This breakthrough technology has won international attention and was published in Small (an internationally-renowned journal of physics and chemistry) in August 2022.

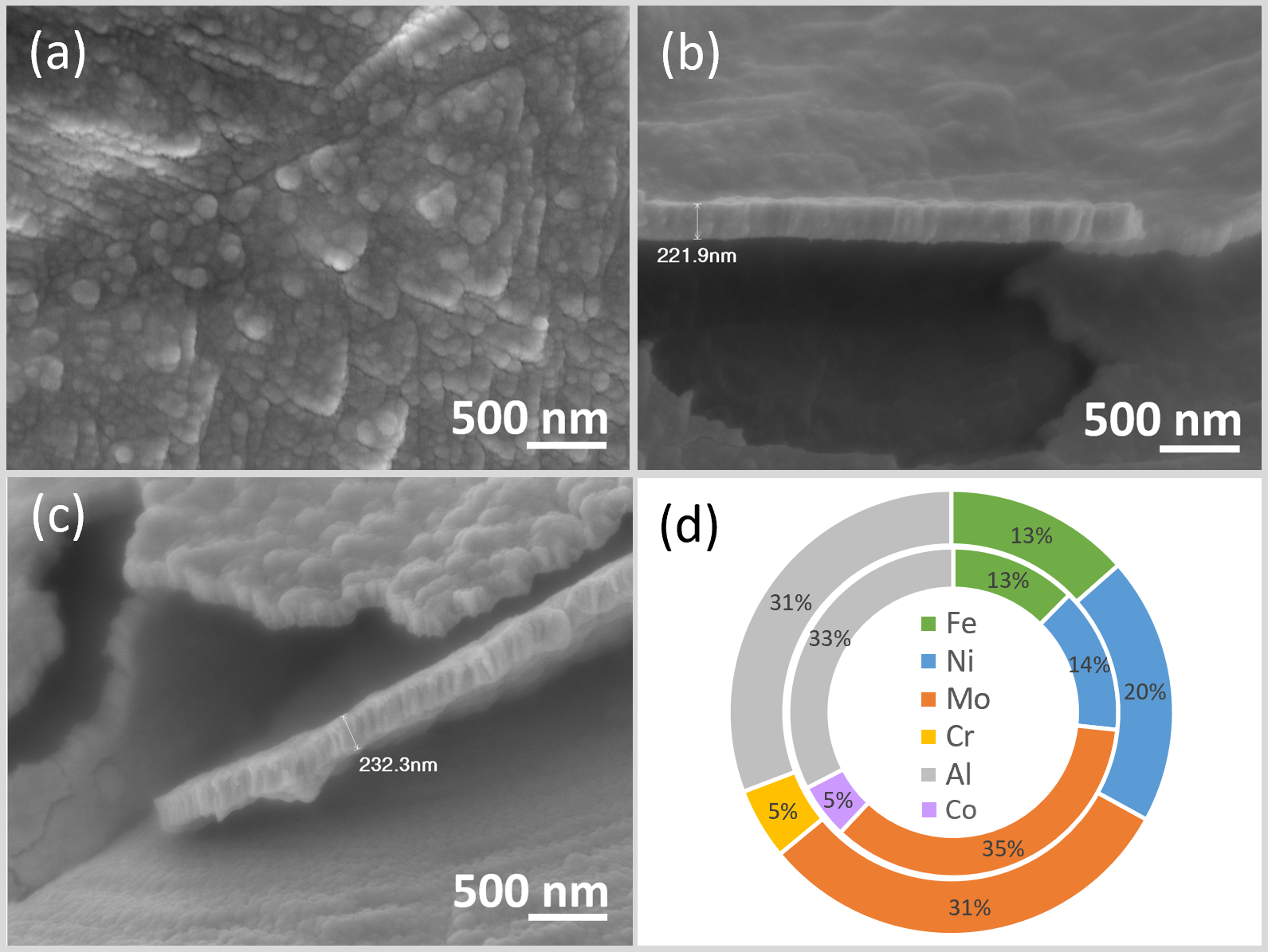

Sample of a high-entropy-alloy thin film

The research team made high-entropy-alloy thin-film catalysts by sputtering deposition, in which thin films are formed by applying a high voltage to the material (target) in a low-pressure space filled with inert gas. Atomic or molecular precipitation accumulates on wafers, glass, or ceramics to form thin films, which have been widely used in semiconductor, optoelectronics, and other related fields.

High-entropy alloy sputtered on substrate has a uniform thickness despite high levels of heterogeneity.

“Quality stability is particularly important for controlling catalyst composition, which is vital for mass production.” according to Siang-Yun Li. Sputtering deposition is a mature mass production technology that enables a wide range of metal elements to be deposited with high uniformity. For example, the golden stainless-steel middle frame of the iPhone 12 is made using this method. The resulting film has a similar composition to that of the target material, which enables researchers to control the ratio of metal elements, allowing for a high degree of repeatability.

In addition to research on high-entropy-alloy thin-film catalysts, the team is also attempting to fabricate bifunctional electrocatalysts. These novel high-entropy materials can catalyze both oxidation and reduction reactions but are difficult to design and manufacture. Siang-Yun Li pointed out that the key to bifunctional electrocatalysts lies in manipulating defects, electronic structures, and deformations. Although high-entropy alloys have a wide range of combinations, their fabrication complexity remains high.

Ding and Li’s team have conducted research on high-entropy materials for more than three years. At first, they were clueless regarding suitable alloy compositions. Eventually, using combinatorial chemistry technology, a method commonly used in drug development, they were able to rapidly synthesize thousands of alloys in a relatively short period of time. The results were then sent to Japan's National Institute for Materials Science (NIMS) and the United States’ National Institute of Standards and Technology (NIST) for analysis.

“In less than two years, we have found the best high-entropy alloy combination among various metal elements,” reported Professor Jyh-Ming Ting , who verified that the sputtered FeNiMoCrAl (iron-nickel-molybdenum-chromium-aluminum) high-entropy-alloy thin-film catalyst outperforms existing commercial options. Not only is it lower in cost, but it also offers increased catalyst stability and activity.

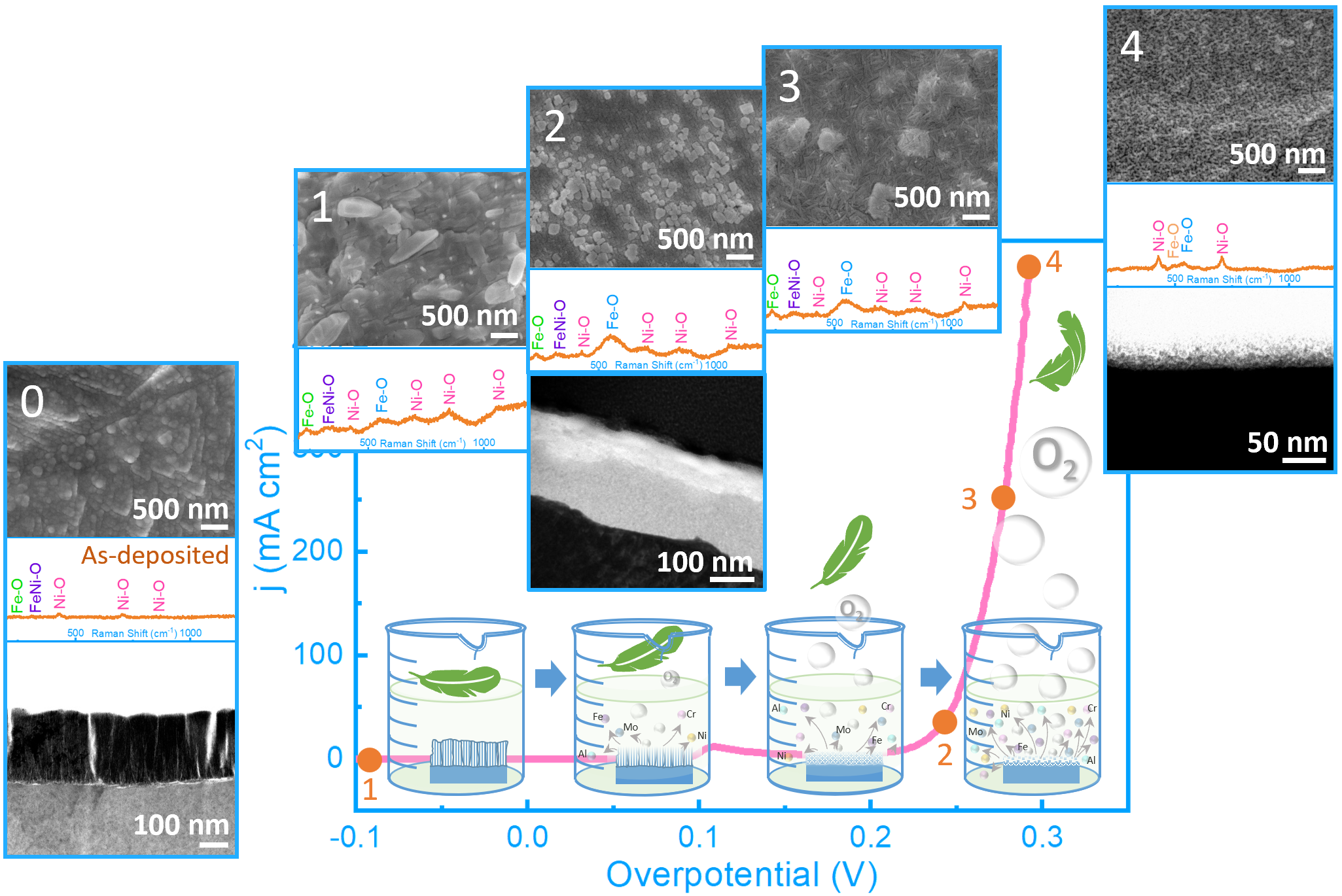

Morphological and structural changes in FeNiMoCrAl high-entropy-alloy thin-film catalysts during oxygen evolution reaction

High-entropy-alloy thin-film catalysts are mainly used in water-splitting to produce hydrogen. As fossil fuels are gradually exhausted, hydrogen energy will become a key technology. In additional to power generation, many iron and steel plants are committed to employing hydrogen to reduce the consumption of iron ore, replacing coke to reduce the amount of carbon emissions. The United Kingdom has launched hydrogen-powered double-decker buses and set up hydrogen refueling stations. Airbus announced the launch of hydrogen-powered aircraft planned for 2035. These examples highlight the importance of hydrogen energy and the role that high-entropy-alloy thin-film catalysts will play.

Provider:

News Center

Date:

2022-11-15